Proper and accurate set up of planer knives

In this article, we will show you how to easily and quickly setup your planer knives using a handy IGM jig.

Even nowadays, some carpenters use outdated and inaccurate methods of proper knife set up. The least precise method I've ever seen was a set up using a wooden bar on the back of the thicknesser. When the knife is shifted up and down for so long that when the drum is slightly spun, the bar moves 1 cm.

Another, a little more modern and accurate method is the so-called magnet "V". Using this method at least allows us to set up knives to the same height.

Other options require specific planer knives or special alterations on the drum. There are spring systems that use springs in the head of the knife shaft and push on the knives. One of the problems is the wear on the springs after a while. Plus they easily clog with dust and chips. Another way is setting the knives according to routed out grooves in the knife. These grooves, however, weaken the knife, which is then prone to breaking. Another disadvantage of these solutions is the high price either of a machine or of the special planing knives.

Forget about lengthy set up of knives

The ever-increasing demand for quality of surfacing and accuracy goes hand in hand with fast and precise set up of planer knives in the spindle. One of the best and most accurate setting jigs is the magnetic setting jig IGM Professional Magnetic Knife Setting Jig, type MUN-001. This magnetic setting jig will help you to simply, accurately and quickly set up a planer knife into the required depth. The main advantage is the set up of all knives into the same height thanks to a micrometer scale. If there was a height difference between the knives, only the higher set one would move into the cut. Then it would dull quickly and the surface wouldn't be smooth and flat. This can't happen if you use your own IGM Professional setting jig.

How it works and how to set up knives in the table and spindle

Setting knives in the spindle

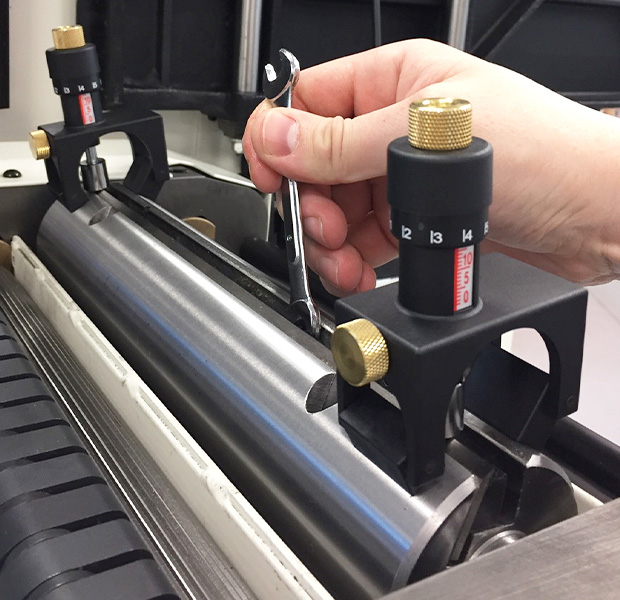

Clamp the magnetic jig on the spindle so that the magnet is above the spindle itself, and then turn the adjusting screw so that the magnet attaches to the spindle. This will give you the default zero value of the magnet height. Do the same on both parts and lock the magnet on the zero default value.

Insert the knife and a wedge into the groove on the spindle and place the jigs on the beginning and the end of the spindle so that the magnets hold the knife at the same point. The jigs should also perpendicular to the axis of the spindle.

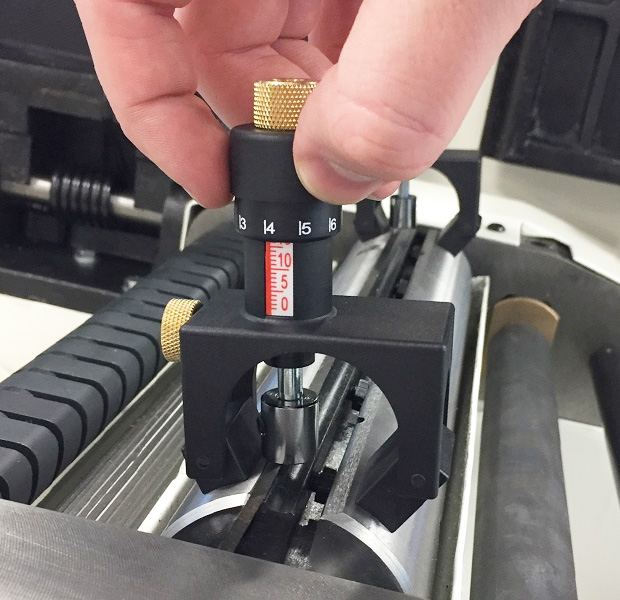

Unlock the first jig and lift the knife over the spindle by up to 1,1 mm using the adjusting screw (the European standard for safe mechanical feeding). One whole rotation will lift the knife by 1,5 mm. (we recommend setting the knives to about 0,7 mm over the zero default value)

Lock the jig in this value and set the same one on the opposite side of the spindle, lock in and tighten all screws in the wedges.

Use the same pre-set in the jig for the rest of the knives in the spindle.

Alignment to tables

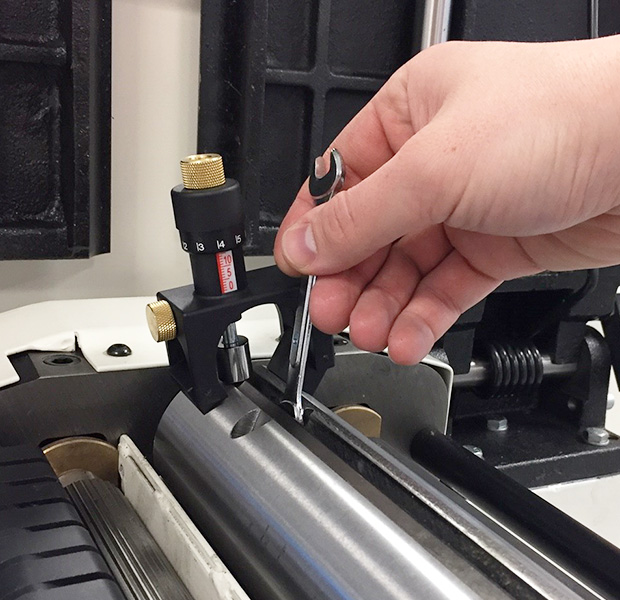

Place the jig on the surface of the table and set the height of the middle magnet so that it touches the surface of the table, lock this position, now the magnet is in zero default position towards the table. Do the same for the other jig. Remove the jigs and place a knife and a wedge into the groove. Place the preset jigs on the spindle so that the left magnet is on the outfeed table and the right magnet on the infeed one, the middle magnet will hold the knife. Do the same for the other side.

Unlock the jigs and alter the knife height by rotating the setting screw by one turn, lock the jig again and set the same on the other side, lock the jigs and secure all wedge screws. Fit the rest of the knives using the preset jigs, do not move the setting screws so that all knives are in the same height. Finally, you can check the blade setting using a straight, small prism that should move exactly 4 mm at the start when the spindle is rotated in the planing directions.

In conclusion

The IGM Professional MUN-001 magnetic jigs are an ideal tool for professional or DIY woodworkers. The jig is supplied in a handy wooden box along with instructions. The body of the jig is made of durable plastic and is fitted with strong magnets. The controls are made of high-quality brass and are zinc coated against corrosion. We can only recommend using this jig to properly set your knives.

Back to what's new