How to select the proper saw blade?

Should you have any questions, please contact us at +420 220 950 910

Saw Blades According to Material:

-

Plastic and

Non-Ferrous

Metals

-

Cement Bonded

Particle Board

Diamond Tooth | 60x longer tool life than other carbide blades.

Ideal for mitre, formatting, handheld and power saws.

Blades for Cetris

-

CORIAN,

Artificial Stone

Designed for: DuPont Corian®, Montelli®, Brien Stone®, LG HI-MACS®, Staron®, Avonite®, Swanstone®, Lyric®, Hanex® a Technistone®.

This type of blade has a Triple Chip Tooth.

Blades for Corian

-

Groove

& Biscuit Joints

Groove Blades: Flat Tooth.

Biscuit Blades: Alternate Top Bevel.

Grooving Blades

Premium Quality | CMT Saw Blades

Distinguishing an ordinary saw blade from a high-quality one is not something difficult:

- Three-layer brazing

- Expansion slot

- Tensioning ring

- Sound dampening channel

- Chrome coating

Premium quality teeth

- The material and thickness of teeth guarantee a very long tool life of the blade

- Up to 5x longer tool life than that of an ordinary saw blade

- The teeth can be sharpened multiple times

CMT Saw Blades Reviews

ORANGE CHROME

INDUSTRIAL / XTREME

ITK PLUS

Designed for professional woodworkers who require high precision, premium quality of cut and long life from their saw blade. These blades guarantee the longest tool life.

Designed for professional woodworkers and finish carpenters, industrial users who run their blades all day long demanding ultimate precision and extended life, while conquering the most challenging applications.

Designed for contractors, smaller woodshops and remodelers. CMT ITK Plus Saw Blades deliver a clean, fast and effortless cut. Designed for wood and wooden composite materials. Excellent price-performance ration.

INDUSTRIAL HW

Teeth made from the strongest micro-grain carbide able to hold its edge in perfect condition for a long time.

THREE-LAYER BRAZING

Silver-copper-silver offers maximum bond of the teeth and body. Reduces brazing damage to the body of the blade.

CHROMED SURFACE

The body is chromed prior to sharpening. This layer protects the blade from corrosion and rust while improving the efficiency of the

CMT Cleaning Emulsion.

SOUND DAMPENING CHANNELS

The channels are filled with a polyurethane compound reducing vibration. This feature increases the quality of cut and lowers the noise level.

EXPANSION SLOTS

Expansion slots provide stability of the blade and prevent blade warping when sawing.

Wiping

The blades are sharpened on multi-axis CNC machines. Fine sharpening of 0,2 µm guarantee extra-clean cuts and extended tool life.

LIFETIME IGM GUARANTEE

We stand behind the quality of ORANGE CHROM AND INDUSTRIAL / XTREME and that is why we offer a "LIFETIME GUARANTEE" on purchased blades. Just leave the service of the tool to use and we will guarantee your warranty.

What to look for

- Features and quality of the body

- Material and protective coating

You should pay attention to the appearance and quality of the body. This is a main distinguishing factor and can help you to tell apart a quality blade from a low-quality one that will last for a limited time only. The body itself along with the finish can tell you a lot. As a rule, an ordinary blade usually has a coarser body, lacks surface treatment and is made from a single sheet of metal, this may lead to swaying or curling of the blade..

Top of the line CMT saw blades are made of German high-strength tool steel (42-48 HRC), laser-cut with maximum precision. Additionally covered with protective layers, either chrome, orange Teflon or protective coating. The saw blade is then perfectly protected from damage, corrosion and is easy to clean. The quality difference is visible in the picture. You can clearly see the difference between a regular saw blade and a CMT blade.

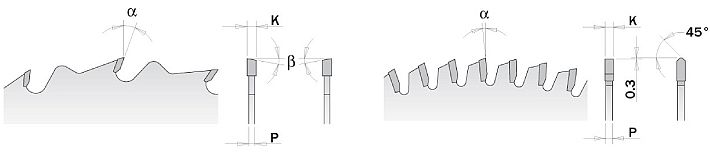

Tooth shape

When sawing in a workshop or out in the garden, you usually use the following types of teeth: flat, alternate top bevel and triple chip grind, or a combination of these. There are also conical or hollow ground teeth designed for special cuts.

The flat tooth and the ATB tooth - usually ideal for solid wood, lumber, OSB boards and plywood.

Triple chip grind tooth - for manufactured boards, like laminated chipboard, plastic or non-ferrous metals.

No. of teeth

Number of teeth, commonly labelled as Z, affects the cleanliness of cut as well as the type of material you can cut.

The number of teeth Z is different for solid wood depending on the moisture of wood and type of cut, either rip or cross cut and the diameter of the blade.

For example, a 160 mm saw blade can be used for:

- Z = 12 teeth for quick and coarse rip cut or for wet wood.

- Z = 24 teeth for universal sawing and general carpentry work.

- Z = 40 teeth and more are blades specially designed for accurate and clean crosscuts in hardwood and softwood when in need of a clean and premium cut quality.

Use blades with a large number of teeth to saw manufactured boards, plastics and non-ferrous metals. 56 teeth for a blade 160 mm in diameter and 96 teeth for a blade 300 mm in diameter.

Teeth and their brazing

- Size and quality of teeth

- Brazing and material

Another important element is the size and quality of the brazed on carbide teeth. With ordinary saw blades, you may find that the teeth are so small that they are not worth sharpening. So even if the saw blade costs less, in the end, its cost is higher due to its short tool life than the quality one. The softest and cheapest carbide teeth are usually fitted onto these blades and in addition to that, they are improperly brazed on. Because of the pressure on low prices, the production processes are accelerating at the cost of reduced quality resulting in overheating of the body and consecutive corruption of the tooth, uneven brazing and irregular tooth dispersion, see picture.

In contrast, the high-quality CMT Chrome, Industrial and Extreme Saw Blades are fitted with "SinterHip" carbide teeth of the highest quality and made of the strongest micro-grain carbide that's able to hold its edge in top shape for a long time. They are gently and accurately brazed on in three layers (silver-copper-silver), securing the consistency and rigidity of the body.

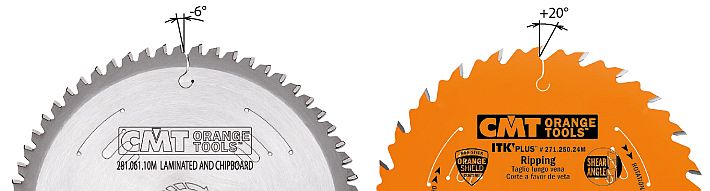

Geometry and sharpening

Hook angle (angle of the teeth) is probably the most important figure. It ranges from +20° for ripping up to -6° for sawing of laminate chipboards on stationary or handheld saws without scoring from the bottom side or for sawing of plastics and non-ferrous metals.

Every CMT blade has its recommended use specified on the body for better orientation. Every CMT tooth is sharpened several times at maximum precision on the most modern CNC sharpeners. The coarseness of a sharpened tooth is down to 0,2 µm on the finest finish.

Stabilization features and soundproofing

- Expansion slots

- Tensioning rings

- Sound dampening channels

The blade can get stuck in wood sometimes, at that moment, the blade can get warped or bend a segment. The CMT ORANGE CHROME series saw blade is protected with 6 expansion slots (arrow pointing up) that secure its stability during expansion due to heat and centrifugal force. Thanks to the hardened tension ring, the CMT saw blades remain stable even in higher temperatures and high-speed use. Majority of the CMT saw blades are fitted with a tensioning ring located in 2/3 of the blade diameter.

The CMT ORANGE CHROME series are also equipped with laser-cut sound dampening channels filled with polyurethane compound significantly reducing the level of noise especially on an empty run. You will appreciate this reduction of noise, especially when cutting for longer periods of time.

-

CORIAN,

Artificial Stone

Designed for: DuPont Corian®, Montelli®, Brien Stone®, LG HI-MACS®, Staron®, Avonite®, Swanstone®, Lyric®, Hanex® a Technistone®.

This type of blade has a Triple Chip Tooth.

Blades for Corian