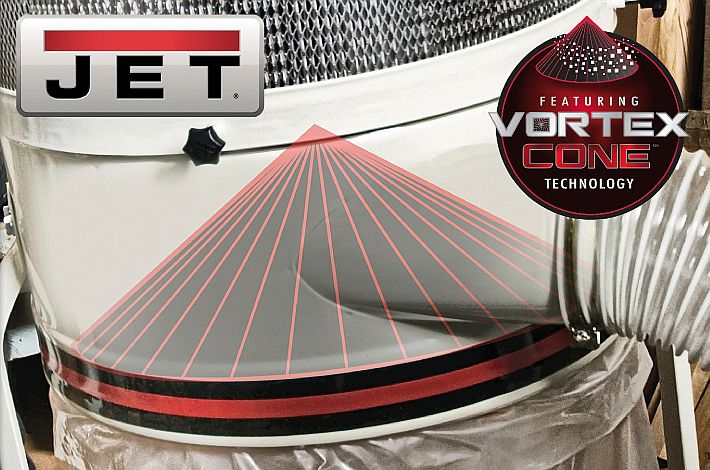

Unique JET dust extraction technology

Functional JET VORTEX CONE dust extraction technology.

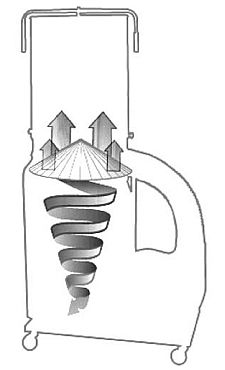

VORTEX CONE is a functional technology separating solid particles in the extractor.

Simply put... The system works by creating a whirlwind carrying solid particles and a cone that encloses the vortex to prevent smaller particles from rising to the upper part of the filter.

Vortex Cone:

• High separating efficiency

• Silent run

• Minimum maintenance

The VORTEX CONE system supplied only by JET for the dust extractors type DC-1100 (one container) and type DC-1900 (two containers).

The VORTEX CONE extractors offer these features:

• 98% of solid particles (chips and sawdust) remains in the container

• Minimum clogging of the container or the JET micro-filtration attachment

• Maintains suction over time

• Minimum maintenance of the filtration bag or the micro-filtration attachment

Here's an example of the micro-filter extension clogging after 20 min of full-on operation, the right one uses the VORTEX CONE technology keeping the filter clean.

What else to appreciate?

The container is secured with a retaining ring, not a simple strap. It's also sealed with foam and solid fabric. You can also clean the container in a matter of seconds. The circular shape helps you to avoid problematic or difficult clamping of the container.

• Easy cleaning of the dust container

• Castors at the bottom of the extractor allow excellent mobility in your workshop.

• Highly efficient motor with cast iron casing ideal for non-stop run.

• Low vibration and silent run thanks to a balanced steel circular fan.

• All controls are of industrial quality.

Efficiency test

We made an efficiency test to make you sure of the quality of VORTEX CONE technology.

Can you imagine your extractor without an upper container?

Check out the short video from the test here...

Back to what's new