One basic rule applies while making wood joints, the more precise and snug joint, the stronger and more durable it is. The ideal joint shape of two wooden parts is a joint with a maximum surface contact with a rectangular cross-section.

A joint with a rectangular cross-section, such as a mortise and tenon joint, has up to twice the strength and stability of a pin joint or a rounded pin. Making such a joint, however, requires experience and precise hands. These joints are usually made with a chisel, eventually a drill or a router, one way or another, you always have to use a chisel to make the round hole square.

There is also an easier and quicker way using a Square Hole Mortiser.

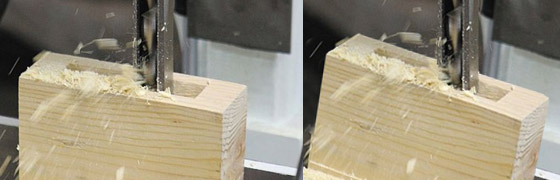

Originally a Japanese invention, the Square Hole Mortiser drills vertically via two chucks when compared to a regular drill mortising machine. Underneath the unit is a three-jaw chuck that houses the spiral drill. Below the drill chuck is a second chuck that is stationary and holds a sharp-pointed mortising bit, this part does not rotate as it is only pushed by the lever and the spiral bit into the material and carves out a square mortise.

Numerous Types and Models in Stock: JET Mortisers, Stationary, Bench or with a Tilting Table.

Quick Mortises

The Bench Mortiser is designed for smaller operations, like mortises into chairs or tables, a drill bit of 10x10 mm is ideal for these jobs.

These Mortisers increase joint precision and significantly reduce the time spent chiselling round corners. Saves loads of time when producing a series of mortises.

Swivelling by 180 °

A huge advantage offered by this Mortiser is the swivelling drill head, which can be rotated 180° after loosening the four screws. This way, you can create mortises into larger parts, for example, to hollow a lock hole into a finished door.

A depth stop fitted on all our mortisers allows drilling into the same depth. An integral part are the side stops that help you to set up the width of the mortise.

With the versatile JET Mortiser 719AS, you can even drill mortises at an angle of 0° to 35° thanks to a tilting table.

The mortising slot bits are installed into the mortiser and cannot be used with normal mortisers or drills because of the spiral bit inside a separate chuck than the carving bit. The spiral bit pre-drills the round hole while the square housing chops out the sides. These bits are easy to sharpen. More about sharpening here: