IGM Manual Edgebanders are handy machines for small and medium-sized woodshops or trade work. Ideal for installations; streamlines banding of curved or angled pieces with a +/-15° edge.

The main feature of the IGM Edgebanders is their variability as they can be used on various edges (ABS, PVC or veneer, width of 10 - 65 mm, thickness of 0,4 - 3 mm) They also provide mobility thanks to their low weight and compact dimensions.

To make sure the edge is firmly branded, you need to keep your machine perfectly adjusted, we will show you how on the following lines.

Setting the right temperature

We recommend setting the temperature to 140 °C, that way the glue will be ready for banding in about 4-5 min.

If you are working in a cold environment, you may increase the temperature to 150 °C, otherwise, the glue might set too quickly and the tape would not hold firmly on the workpiece. Make sure not to exceed the recommended temperature, overheated glue can lose its strength.

When the temperature reaches 120 °C, you can let the machine run idle to accelerate the heating and mixing process.

Setting the infeed tape guide

Use the scale on the left side of the infeed guide to properly set up the height, then hold down the tape between the scale and the base. Now your infeed guide is properly set up and should not lift of brake the feeding process.

What glue should I use and what difference does it make

It is necessary to use low-melting IGM glues to secure the proper function of the edgebanders - using glues with different melting points and properties may lead to incorrect banding or even damaging the machine.

Avoid using similar melting glues - their melting point may differ and can damage the feeding system.

Another important factor is feed speed. IGM Edgebanders have a range of feed speed of 2-6m/min., however, some glues are designed for higher feed speeds of 10-20 m/min. These glues are designed for mechanical banding and are thus not suitable for manual edgebanding.

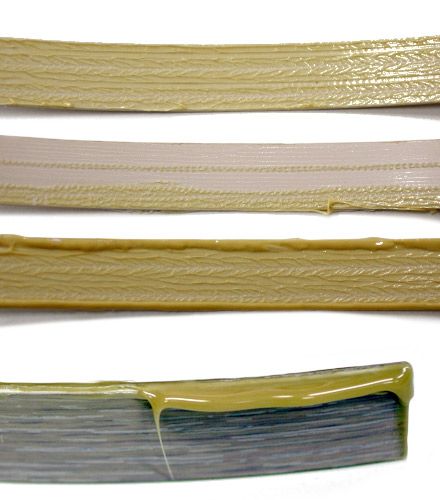

Adjusting glue application

If the edgebander is properly set up, the glue should be applied along the whole width of the edge in a continuous layer without overflows. If the amount of glue is too small but the layer is continous, or there is too much of glue and overflows, you will need to adjust the amount of glue using the regulation of glue knob. Only adjust glue amount when the glue has melted, otherwise, you can damage the regulation knob.

If the glue is not equally distributed along the width of the tape, you will need to adjust the pressure control using two screws on the back of the machine. Adjust the pressure only by one rotation of the screw and then test it out on a sample piece.

Correct use of the corner guide

If you are glueing in a corner, you will need to use the corner guide supplied with the IGM edgebander.

Attach the guide to the base of the machine using the supplied screw. We recommend lowering the feed speed and waiting for the tape to reach the corner when banding inner corners. Apply pressure against the edge to secure a proper fit. You can only band edges from right to left, so make sure to first apply tape on the left side of the corner and then on the right side after turning the workpiece over.

The importance of using a tape holder

To secure the proper feeding of your tape, we recommend using the 142-BC25 Tape Holder.

The tape is safely stored in the holder, does not get tangled and cannot get damaged.

When banding a veneer, the holder is virtually essential as the veneer would break without proper support. The tape holder substantially streamlines your banding.

When to attach the edgebander to a table

Worktable for IGM Edgebanders comes in handy when banding smaller workpieces, like shelves, drawer heads or parts of furniture. With an edgebander secured in the worktable, you can also band thin edges or curved pieces with much more precision that when handheld. Its also ideal for situations when vacuum suction is not an option.

The Worktable for IGM Edgebanders comes fitted with a socket and a switch allowing simple control when working. The IGM PD80 Edgeband Trimmer can also be attached to the worktable. That way you can comfortably trim and round the banded edge. The table comes fitted with trimming scissors that can cut up to 2 mm thick tape and a set of magnetic pads to support the workpiece without scratching the surface. The table also holds a reversible tape holder, adjustable according to diameters of your tape, holds tens of meters of tape.