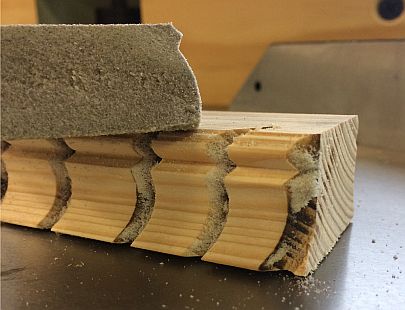

Perfectly sanded mouldings

Many customers use sanding sponges for uneven surfaces or mouldings. But in this day and age, one can use the IGM Elastic sanding sponges to sand mouldings or use in between varnishing. They’re far more efficient.

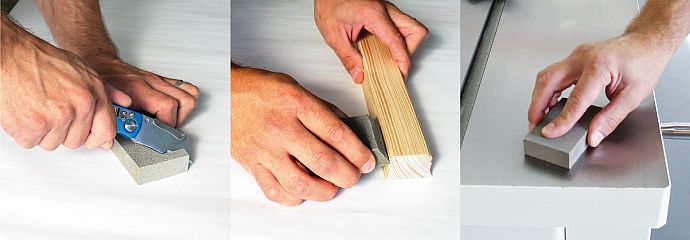

The main advantage of the elastic sanding blocks is their compact structure, adaptability and widespread use for all sorts of materials. Because the abrasive is not only on the surface but in fact the whole block, you can profile the elastic sponge to mirror your moulding or simply cut out the desired shape.

The Elastic foam sanding blocks are made from polyurethane binder, which allows extensive adaptability of the sanding tool to the sanded surface simplifying, accelerating and streamlining the whole process of surface treatment. The elasticity of the foam block offers the sanding of uneven, porous and difficult to reach spots such as corners, openings etc

Examples of possible use:

• Wood Workshop (sanding, smoothing and polishing of wood, complex profiles)

• Metal Workshop (metal grinding, polishing, refining, deburring, …)

• Paint Shop (removal of old paint and varnish, polishing, …)

• Industrial Workshop (contact cleaning, grinding, finishing, …)

• Household (cleaning and removing deposits in bathes or on stoves, …)

• Garden (rust removal before painting, …)

• Sport (removal of rust on skates, sharpening of ski edges, ski base refining …)

• Dimensions: 20 x 50 x 80 mm

• Coarseness: Extra fine, fine, medium

Order the IGM Sanding Sponges, now with an additional discount of 10% when buying more than 10 pcs.

Back to what's new