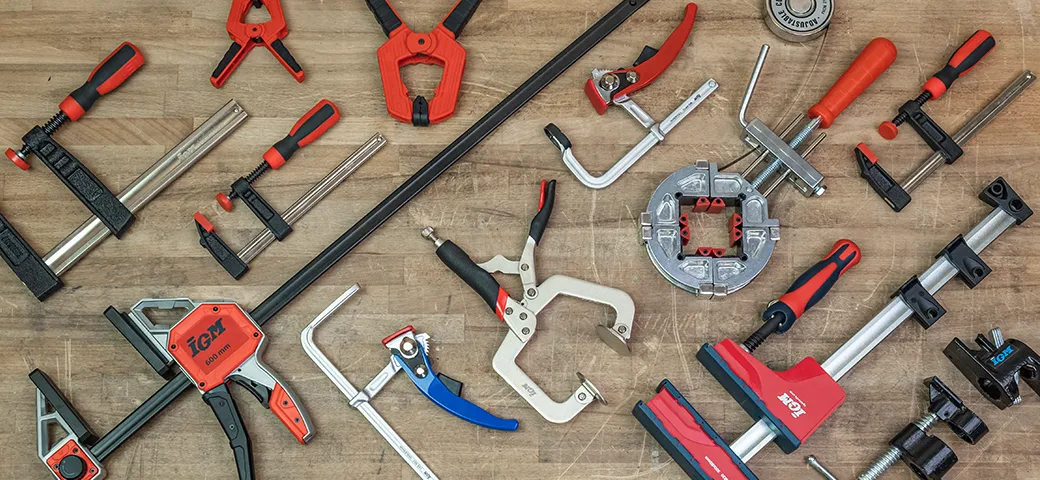

Clamps and various types of clamps for wood are an essential part of every professional woodworker’s and DIYer’s workshop. If you are looking for suitable clamps but are unsure which ones to choose, we have prepared a complete guide to the world of clamps and fastening tools. Whether for small tasks or massive boards, this overview will help you make a clear choice.

Types of Woodworking Clamps

When choosing the right tools, it is important to consider the type of work you plan to do and the kind of material you will be working with. Different types of clamps can be categorized into several basic groups, which vary according to the material and the method of use. Each of these types can come in countless varieties and can be used for many purposes beyond their primary intended use.

The woodworking clamps can be categorized as follows:

Woodworking F clamps

Secure and hold tight

The classic woodworking F clamp is the most common and widely utilized type of clamping tool. It is used by almost every woodworker and is suitable for any situation where two items need to be clamped together. It’s an excellent addition to any workshop and is useful for tasks beyond just woodworking.

F clamps are generally available in lengths ranging from 150 mm to 1 meter. The jaws are equipped with plastic covers to protect the workpiece from damage. They feature profiled cast iron arms attached to a steel bar. The handles are coated with a light yet secure silicone overlay, known as Soft-Grip, to ensure a better grip during use. In addition, you won’t feel the need to use too much force to keep your hand from slipping, unlike with traditional wooden handles.

One-handed quick-release clamps

Extra pair of hands that are always available

A quick-release bar clamp is an excellent tool when two hands are not enough. It comes in handy for gluing or screwing of individual parts, to secure material to the bench a pillar drill, a machine’s guide rail and to other activities, where you need to manage with one hand only. It performs its function immediately and without need for adjustments.

The one-handed quick-release bar clamp is the fastest tool for securing a workpiece. These tools are specially intended for clasping components; however, they are not suitable for joining larger surfaces and massive materials together. It is necessary to keep in mind that if you clamp workpieces over a long period, the clamping pressure may decrease. Therefore, it is advisable to replace them with parallel jaw clamps.

At first glance, one-handed clamps can be recognized by their distinctive mechanism, which includes a manual lock for quick release of the jaws and a “protruding” bar. They feature durable plastic or aluminum jaws with rubber tips and sliding rails made of hardened steel, with lengths ranging from 150 mm to 1200 mm depending on the jaw material.

Quick lever clamps

Subtitutes all other clamps

The lever clamp is known for the easy clamping system. It has a robust all-metal body and durable construction, which eliminates concerns about damage or wear, unlike plastic one-handed clamps. In addition, you have two types of these great and, in many cases, unmatched helpers at your disposal.

The blue range of the IGM lever clamps is particularly notable for its compatibility with guide rails from popular brands, such as FESTOOL, Makita, Bosch, Metabo etc., as their jaws can be inserted into a 12 mm guide T-slot. Additionally, the blue lever clamps are handy for securing wood to the workbench. They offer excellent performance, and thanks to their plastic covers, prevent damage to the clamped workpiece.

The red range of the lever clamps is distinguished by a high clamping force, which exceeds 400 kg. Compared to the blue range, these clamps cannot be inserted into guide slots, but they are highly versatile in terms of usability. The red lever clamp is likely to become your favorite tool quickly. It efficiently replaces traditional screw clamps, one-handed clamps, and parallel clamps while maintaining the simplicity of one-handed operation, robust construction, and high clamping pressure.

They are simply the best.

Face clamps

Hold (not only) pocket hole jigs gently but firmly

The face clamp is a special tool characterized by compatibility with IGM and Kreg pocket hole and assembly jigs. If these handy tools are a part of your workshop, this type of clamp is an essential addition that you will likely find indispensable.

Additionally, without these jigs you can benefit from the face clamp’s features, such as its large clamping pads that keep workpieces aligned. The smooth pressure control and the ability to fine-tune it using a screw are particularly useful. It is ideal for working with delicate materials without the risk of damage.

Parallel jaw clamps

Simple gluing of joint boards and cabinet components

The parallel jaw clamps, also known as cabinet clamps, are essential tools for joint boards and other large projects that you’ll be able to handle with confidence. Their large clamping surface remain parallel even under pressure, ensuring stability. Additionally, by rotating the jaws, the clamp can be converted into a spreader.

IGM offers two versions of parallel jaw clamps. The basic difference between them is the clamping pressure. While the standard cabinet parallel jaw clamps provide a pressure of only up to 180 kg, the HD models boast with pressure up to 800 kg. That’s quite ahelper! Even when gluing the largest joint boards, you don’t need to worry aboutit shifting due to insufficient pressure.

The parallel clamp also features the patented anti-slip system with swivelling handle, which can help to secure even the most unstable workpiece. Additionally, a set of parallel clamp blocks is a great aid for gluing frame constructions andholding very heavy boards.

Thanks to the bar length of up to 150 cm, you can handle a solid table top even without high-pressure pressing machines for joint boards, like those found in a professional workshop. With cabinet clamps, you needn’t to worry about producing or assembling cabinet boxes. You can perform all these tasks and more with ease.

Pipe clamps

Don’t be limited by size

Compared to parallel clamps pipe clamps offer a significant advantage: you are limited only by the length of the steel plumping pipe. If that’s not enough, join two of them together! How does it work? You screw one part of the jaws on the steel pipe with a 26,9 mm diameter and a G 3/4" BSP thread, while the other jaw slides onto the opposite end of the pipe. The clamp is now ready to use. The jaws are equipped with feet that offer better stability and performance. The whole construction is made from cast iron with clamping by a massive handle.

As with parallel clamps, there is no need to own expensive high-pressure pressing machines to achieve satisfactory results. However, the clamping pressure and stability when clasping material do not reach the parallel jaws clamps level.

But be careful. Due to the variable treatment of the pipes used, there is an increased risk of glue contamination, which may hinder the movement of the sliding jaw. However, considering the utility value relative to the purchase price, pipe clamps are the most cost-effective solution for gluing larger joint boards or clamping longer workpieces.

Frame clamps

A special tool for large-scale frames

Frame clamps are, as the name suggests, specifically designed for making frames, especially large ones. While other types of clamps can be used as substitutes, only frame clamps provide optimal results in terms of both quality and ease of use.

There are two variants of frame clamps available: one is a fully plastic model with a nylon strap, and the other features a plastic reel and swinging edge elements. Both types can be used to clamp irregular shapes as well. These two models are especially appreciated by DIY’ers.

Professional work is facilitated by a fully metal frame clamp with an aluminum body for precise and secure clamping. It is also equipped with swinging edge elements, but the clamping is managed with the help of a steel strap located in the reel body. This ensures safe and quick handling.

Spring clamps

Big clothespin for smaller clamping

The spring clamp is not a clamp in the traditional sense. It is flexible and it operates with a very light squeeze, making it comparable to a clothespin. Use it for quick and easy clamping of smaller objects, such as various slats or decorative mouldings, where high clamping pressure is not required and excessive pressure could cause damage.

Despite its gentle action, the spring clamp is highly durable. The strong, heat-tempered steel spring withstands almost any use without leaving pressure marks or causing other damage. The swivelling pads can help to better clamp a workpiece, and the rubber handle prevent the tool from slipping out of your hand.

Wooden Cam Clamps

Ideal for Model Makers and Instrument Makers

These clamps, as the name suggests, feature wooden clamping jaws, but the bar is made of steel to prevent unintended movement. On our e-shop, we offer wooden clamps clamps in various lengths ranging from 290 to 690 mm, all equipped with soft cork pads to protect the workpiece from damage.

Wooden cam clamps do not provide high clamping pressure. As a result, they are suitable for delicate and sensitive workpieces that could be damaged or crushed by the pressure of a traditional woodworking clamp if the clamping pressure is misjudged.

These tools are particularly useful for fine work such as model making, instrument making, or veneer gluing and edge work when finishing details or restoring old furniture.

If you frequently use clamps as faithful assistants in your workshop, you might also need replacement plastic jaw pads, which wear out over time and can leave unwanted marks on clamped workpieces. You can find them along with other accessories for all main types of clamps on our e-shop.

For organizing and storing clamps, a compact wall-mounted rack. Although it is primarily designed for parallel and F clamps, it can easily accommodate other types of clamps as well. This will help keep your workspace clutter-free and ensure that your clamps are always ready for use.