Bandsaw blade should always be as thick as possible, depending on the circumstances,

however never thicker than what your saw allows. The information should also be available in the user’s

manual.

Blade life

The thicker the blade is, the stronger pressure it can withstand without deviating. Thick

bandsaw blades generally have longer life and overall durability and are also more accurate

when making straight cuts.

Cut radius

Another key factor for determining the right blade width is the intended cut radius – for making curves,

a thinner blade is ideal, while for straight lines you will need a thicker one. The thick blade is also

good for resawing.

Note:

It is generally advisable to reserve specific blades for specific tasks. The way the blade is being used

and the types of cuts it makes affect its shape over time – that is why for instance thin blades used

for cutting curves are not suitable for making cuts of straight parts.

|

Blade width (Y)

|

Minimal radius (X)

|

|

25 mm

|

175 mm

|

|

20 mm

|

140 mm

|

|

16 mm

|

100 mm

|

|

13 mm

|

65 mm

|

|

10 mm

|

40 mm

|

|

8 mm

|

25 mm

|

|

6 mm

|

15 mm

|

|

3 mm

|

3 mm

|

Tooth Pitch or TPI

Coarse tooth (tpi 2, tpi 3 and tpi 4)

It is used for for deep cuts and quick rough wood splits. It is suitable for cutting longitudinal,

soft and raw (green) lumber.

Middle tooth (tpi 4, tpi 6 and tpi 8)

It is used for normal cutting and is the most commonly used tooth size. Used for longitudinal and

transverse cuts, it offers the best ratio between speed and cut clarity.

Fine tooth (tpi 10 and tpi 14)

It is used for fine cutting and where high cut purity is required. It is most often used for cutting

plywood or board material up to 10 mm height.

|

TPI designation

|

Distance between peaks in [mm]

|

|

2 TPI

|

13 mm

|

|

3 TPI

|

8,5 mm

|

|

4 TPI

|

6 mm

|

|

6 TPI

|

4 mm

|

|

8 TPI

|

3 mm

|

|

10 TPI

|

2,5 mm

|

|

14 TPI

|

1,8 mm

|

TPI stands for “Teeth Per Inch”. The higher the TPI, the smaller the pitch.

CUT SMOOTHENESS

A rule of thumb is that higher TPI is capable of making smoother more accurate cuts while low TPI makes rough

cuts which don’t require too much accuracy and finish quality.

SPEED AND HEIGHT OF CUT

Higher TPI however means lower material clearance as well as smaller maximum diameter of material (height of

cut).

So logically, higher TPI is to be used for fine and precise work on thinner workpieces while low TPI is

fit for deeper cuts or swift and coarse cutting of raw material.

|

|

Low TPI

|

High TPI

|

|

Cut characteristic

|

rough

|

fine and precise

|

|

Diameter of cut

|

higher cuts

|

thin cuts

|

|

Cut speed

|

high speed

|

lower cut speed

|

|

Direction of cut

|

with the grain (rip cut)

|

across the grain (cross-cut)

|

REGULAR, HOOK or SKIP? Choose the right teeth shape.

Teeth on a bandsaw blade can come in various shapes. Generally, you’re likely to see these three most widely used

types – Regular, Hook and Skip.

- Universal most frequently used type

- The teeth have a regular shape with a 0° angle

- Tends to have a higher TPI

- Mainly suitable for fine cuts in most wood types

- Similarly to Regular has a 0° angle teeth curvature

- Teeth are far apart, almost like every other tooth is missing

- Not as aggressive as Hook, but not for smooth cuts either

- Highly suitable for rough cutting of raw material.

- Usually has a lower TPI

- Teeth are curved at a 10° angle

- Capable of aggressive cuts, for instance in harder and more resilient wood

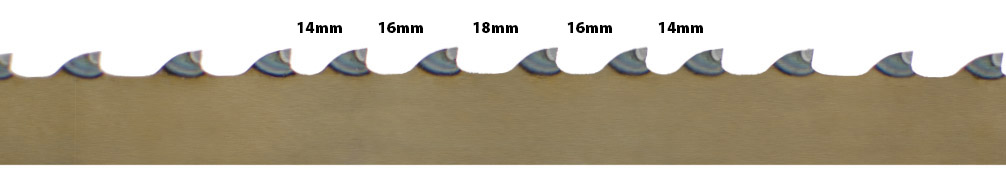

RESAWKING (Blades with Carbide Teeth)

Just like table saw blades, bandsaw blades are also available

with carbide teeth. Their main advantage is that they are durable and precise and also have an

exceptionally long life. With carbide teeth, it is possible to make otherwise very difficult cuts,

whether in the sense of wood hardness or need for material economy.

This makes such blade very useful for work with more valuable, for instance exotic types of wood, for which thin

and fine cut is of utmost necessity so that there is as small a kerf as possible. It also reduces the need for

planing – the edges require merely just a little sanding.